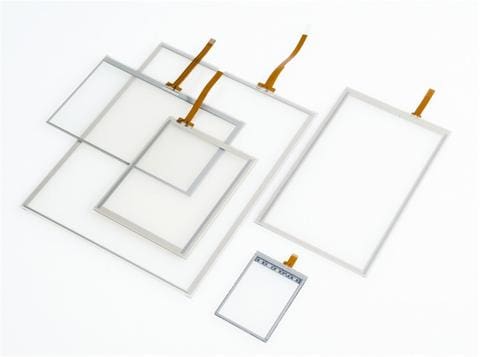

Touch Screens: Plazmo's state of the art manufacturing facilities have the capabilities to produce various types of touch screens. Our customers appreciate our attention to detail and ability to produce premium quality OEM replacements for many different sizes, styles of touch screens.

Touch panels, or touch screens, have become an integral part of everyday for millions and millions of people around the world. Daily uses include Bank ATMs, ticket vending machines, car navigation, kiosks, gaming and casinos, handheld video games, industrial control panels, smartphones and tablet devices.

Depending on the application's use and volume, touch screen panels can wear out from daily operation. Many factors come into play such as outdoor elements, oils from fingers, heavy stylus use, mineral spirits, alcohol, fuel, gasoline and other fluids. When the touch screen impacts the utility of the device or the customer experience, it's time to look at replacement. The good news is replacing a touch screen is much more cost effective than replacing the entire LCD screen. Plazmo manufactures premium quality OEM touch panel replacements for all manufacturers and applications.

Resistive Film Touch Screens: This popular method is also called pressure sensing or analog-resistive film. These are used in a wide range of applications. With this method, the position on screen contacted by a finger, stylus, or other object is detected using changes in pressure. The monitor features a simple internal structure: a glass screen and a film screen separated by a narrow gap, each with a transparent electrode film (electrode layer) attached.

The advantages include the simple structure and therefore a low-cost to manufacture. Drawbacks include lower light transmittance.

Capacitive Touch Screens: These are probably the second most widely used. There are two types: surface or projected. Surface capacitive panels are often used in relatively large panels. Inside these panels, a transparent electrode film (electrode layer) is placed atop a glass substrate, covered by a protective cover.

Projected capacitive touch screens are often used for smaller screen sizes than surface capacitive touch panels. They've attracted significant attention in mobile devices. The internal structure of these touch panels consists of a substrate incorporating an IC chip for processing computations, over which is a layer of numerous transparent electrodes is positioned in specific patterns. The surface is covered with an insulating glass or plastic cover.

These panel types feature strong resistance to dust and water drops and high durability and scratch resistance. In addition, their light transmittance is higher, as compared to resistive film touch screens.

On the other hand, these touch screens require either a finger or a special stylus. They cannot be operated while wearing gloves, and they are susceptible to the effects of nearby metal structures.

Surface Acoustic Wave (SAW) Touch Screens: these panels were developed mainly to address the drawbacks of low light transmittance in resistive film touch panels. Aside from standalone LCD monitors, these are widely used in public spaces, in devices like point-of-sale terminals, ATMs, and electronic kiosks.

The internal structure of these panels is designed so that multiple piezoelectric transducers arranged in the corners of a glass substrate transmit ultrasound surface elastic waves as vibrations in the panel surface, which are received by transducers installed opposite the transmitting ones.

The strengths of this type of touch panel include high light transmittance and superior visibility, since the structure requires no film or transparent electrodes on the screen. Weak points include compatibility with only fingers and soft objects (such as gloves) that absorb ultrasound surface elastic waves. These panels require special-purpose styluses and may react to substances like water drops or small insects on the panel.

Optical (Infrared) Touch Screens: The category of optical touch panels includes multiple sensing methods. The number of products employing infrared optical imaging touch panels based on infrared image sensors to sense position through triangulation has grown in recent years, chiefly among larger panels.

Electromagnetic Induction Touch Screens: This type differs somewhat from the above touch panels and is used primarily in specialty devices like LCD graphics tablets, tablet PCs, and photo sticker booths. Since the technology was intended for use in graphics tablets, it offers superior sensor precision. However, since a special-purpose stylus is used for input, input using a finger or a general-purpose stylus is not possible, and the method has limited applications.

| Sensing Method | Resistive | Capacitive | SAW | Optical | Electro-magnetic |

| Light transmitt-ance | Poor | Good | Good | Best | Best |

| Finger Touch | Yes | Yes | Yes | Yes | No |

| Glove Touch | Yes | No | Yes | Yes | No |

| Stylus Touch | Yes | Poor | Good | Good | Yes, special stylus |

| Durability | Poor | Best | Best | Best | Best |

| Resistance to water droplets | Best | Best | Poor | Good | Best |

| Cost | Good | High | Good | High | High |